Morrill's clocks

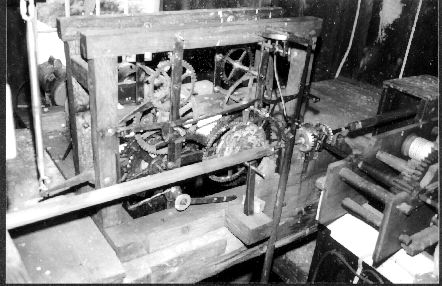

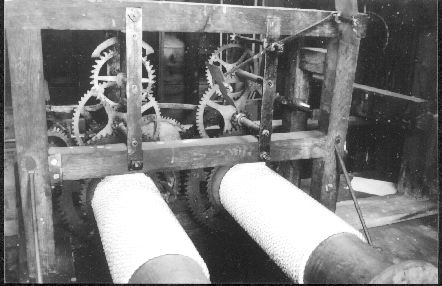

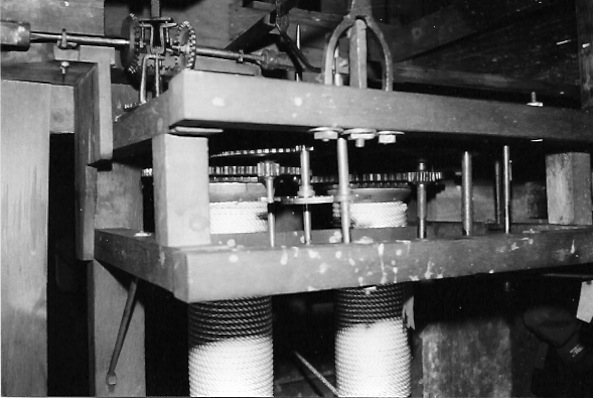

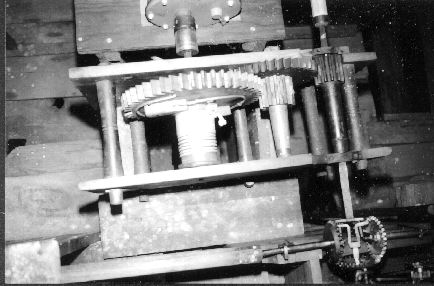

are all flatbeds, with decoratively spoked wheels and pinwheel

escapements, and don't require an auxiliary drive for the outside dial hands.

A Bit of Speculation--Who Was

The Maker?--and Similar Clocks

Unfortunately, there is little information to be found that would lead

to the identity of the maker of the clock. In 1890 the Town Historian

wrote: "After this (the 1839 remodelling of the 1794 church) Josiah

Green purchased a large clock, which he put into the steeple to remain

at his pleasure, for the use of the society and the public." The church

records suffer from poor to no record-keeping in the late 1830's---early

1840's, thus that source is of little help.

Josiah Green, born in Stoneham, Massachusetts, on 25 May, 1790, was the

eldest of nine children born to Captain Josiah Green, Jr. and Susannah

(Buckman) Green, who removed to Salisbury from Stoneham, Massachusetts,

in 1800. Josiah apprenticed at 14 to a carpenter/builder in South

Reading (now Wakefield, a suburb of Boston), Massachusetts, in 1804. He

married Clarissa Sweetser in Wakefield on 21 January, 1817, and upon

returning to Salisbury shortly afterwards, built a number of houses,

including one for himself, in which he lived for a few years. Of

particular interest is this biographical note in the Green genealogy:

"[Josiah] removed thence to the

homestead, opposite to which, in 1820, he opened a store and was in

trade until 1840, although some years previous he followed the

occupation of clock repairing6,

in which he gained a great reputation."

In this occupation he was succeeded by his son, Sylvester Walker, after

the latter's return from the 1849 gold-driven diaspora of New

Englanders.

6 It is rather curious that

the Salisbury historian only twice in some 886 pages ever refers to

making clocks---when mentioning the Blaisdell's of Salisbury and

Chester, and a Blaisdell clock owner living in Salisbury in 1890. In

another reference to clocks, in about 1830 Oliver Tucker (Salisbury

Genealogy) is said merely to have "learned the trade of clock repairer

with Mr. Durgin (Gershon Durgin, a known maker) at Andover...", rather

than being apprenticed to a clockmaker. The suspicion is that "clock

repairer" was a generic term for anyone involved with the trade.

I also found this in the History of Boscawen and Webster while

researching this clock: "Jeremiah Gerrish was a gunsmith and repairer

of clocks and watches, and made cut-nails...cutting them out of

hoop-iron with large shears driven by horsepower..."

6

The genealogical record goes on:

"Sylvester prefers a New England home,

and remains on the homestead, following his father's trade of clock

repairing, in which he enjoys a most excellent reputation throughout

central New Hampshire."

Josiah Green died at age 75, on 22 February, 1866.

Joseph Chadwick7, Morrill's contemporary and competitor

(regardless that he married Morrill's older sister) in Boscawen is not

known to have made tower clocks (he was in Lebanon, New Hampshire, by

1821) nor were there any other known tower clock makers (other than

Benjamin Morrill, whose clocks are of a different design) at work in the

area. Nathaniel Atkinson of Boscawen was 86 years old in 1839,

therefore it's unlikely that he made the clock. By way of comparison,

the two somewhat contemporaneous wood-plate/brass-wheel clocks

illustrated in Parsons' New Hampshire Clocks and Clockmakers

(Ppg. 140-143) were checked, but these clocks use count-wheel striking,

and their maker's locales and at-work dates preclude the possibility

that they were the makers.

The time train reminds one of the trains of various later---primarily

brass movement---house clocks, particularly those with an idler

(sometimes called the second wheel) between the minute arbor and the

time train. The distinctive diamond-tipped hands---a shape rarely found

on a tower clock---remind one of the hands of a much smaller house

clock. These resemblances lend some credence to the idea that a

repairer of clocks built this clock.

A thorough search of Parsons' book beyond the above-mentioned clocks

yields nothing in the way of hints concerning a possible maker's identity.

Donald K. Packard's When New Hampshire was a Clockmaking Center

is also of no help in suggesting a maker.

7 Chadwick could have made

the clock, but it is rather unlikely. His life is not thoroughly

documented, but he has been traced via census records to Lebanon, New

Hampshire, in the 1820's, and Norwich, Vermont, in the late

1830's---early 1840's.

7

There is the distinct possibility that Josiah Green himself made the

clock "...which he put into the steeple to remain at his pleasure..."

He may have purchased some of the parts and assembled them, rather than

having "purchased a large clock" from an unnamed and unidentified maker,

or he may have made the parts. The frame certainly was made by someone

intimately conversant with the wood joinery of the times, yet the

overall construction and the utilitarian---perhaps even

crude---appearance of the clock's other parts suggests that it was made

by someone who had not apprenticed to a clockmaker, but who had picked

up bits and pieces of the clockmaker's skills and designed and built a

tower clock whose train layout is very similar to those of smaller

clocks. There is an admixture of sophistication---the pendulum box;

makeshift design---the wedge-held pendulum bob; and old-fashioned design

seen in the frame style that poses an intriguing question concerning

just what sources of information the maker consulted in designing the

clock. None of Green's contemporaries (Thomas Woolson, Jr. and Luther

Elliott in Amherst, Stephen Hasham in Charlestown, and Benjamin Morrill,

the last just a few miles away in Boscawen) made anything but flatbed

tower clocks, nor are there any known chairframe clocks in either New

Hampshire or Massachusetts. The sole exception is the (possible

chairframe) clock Daniel Burnap made for South Hadley, Massachusetts, in

1802-3, which has disappeared.

A record8 of the order for this South Hadley clock is signed

"Ruggles Woodbridge, for the Committee" and dated "South Hadley, Nov.

2nd 1802." George D. Seymour9 wrote of "...the unbelievably

big models for the hands of a steeple clock." in Burnap's Andover,

Connecticut, attic work-room. Mr. Seymour also quotes the Burnap Papers

(Appendix 6); concerning the "meeting-house clock for South Hadley,"

and the "steple" clock therefor, of which Burnap wrote; "I think it is a

matter of uncertainty whether I shall be able to finish it so as to get

it to you before sleighing." (Appendix 5.) Ela Burnap's (his nephew

and one time apprentice), correspondence on tower clocks from Rochester,

New York (February 20, 1837), asks for construction details for a tower

clock, referring to "that clock we made when I was with you." Ela was

born in 1784, therefore he could not have seen the "clock we made when I

was with you" before 1798-1800, assuming he started his apprenticeship

at 14 to 16 years of age.

8 HOOPES, Penrose R.

The Shop Records of Daniel Burnap:

The Connecticut Historical Society, 1958. Pg. 31.

9 SEYMOUR, George Dudley, Daniel Burnap---Master Clockmaker:

NAWCC BULLETIN # 105, Pg. 811.

8

A chairframe clock10 attributed to Burnap is in the

collections of the Connecticut Historical Society, but the only

(extremely tenuous) link to Burnap is found in the description of a

similar clock in his Memorandum Book.

Regardless of who the maker of the Salisbury Heights tower clock was, it

is an interesting and now-documented clock, and as a side benefit, four

more names---Josiah and Sylvester Green, Oliver Tucker and Jeremiah

Gerrish---have been added to the ranks of New Hampshire horologists.

10 See Early American Tower Clocks, Ppg.25 - 27,

and Shop Records of Daniel Burnap;

"Form of the Suffield Clock."

9

BIBLIOGRAPHY

BISSELL, Charles, THE SUFFIELD TOWER CLOCKWORKS:

BULLETIN of the Connecticut Historical Society, Volume 27, Number

2.

COFFIN, Charles Carleton, Comp., THE HISTORY of BOSCAWEN and WEBSTER, N.H.

from 1733 to 1878. Printed by the Republican

Press Association, Concord, New Hampshire. 1878.

DEARBORN, John J., Coll., THE HISTORY of SALISBURY NEW HAMPSHIRE,

from date of settlement to the present time.

Printed by

William E. Moore, Manchester, New Hampshire. 1890.

HOOPES, Penrose Robinson,

CONNECTICUT CLOCKMAKERS of the EIGHTEENTH CENTURY;

Edwin Valentine Mitchell,

Hartford, Connecticut. 1930.

____, SHOP RECORDS OF DANIEL BURNAP;

The Connecticut Historical Society, Hartford, Connecticut. 1958.

PACKARD, Donald K., WHEN NEW HAMPSHIRE was a CLOCKMAKING CENTER;

Historical New Hampshire, An occasional

publication of the

New Hampshire Historical Society: April, 1950.

PARSONS, Charles S., NEW HAMPSHIRE CLOCKS and CLOCKMAKERS:

Adams-Brown Co., Exeter, New Hampshire. 1976.

SHELLEY, Frederick M., EARLY AMERICAN TOWER CLOCKS:

National Association of Watch and Clock Collectors, Columbia,

Pennsylvania. 1999

10

Return to Page Three

of the late Donn Haven Lathrop's three main pages.

Compare Donn's

original

version of this page

if it still exists.

To comment on this page, please

|